Listen to this blog

Fashion & Apparel makes up a small portion of US imports but contributes to a disproportionate amount of the tariffs collected by the United States government. As the White House continues to hint at an expansion of tariffs to include a wide range of consumer goods that includes apparel and footwear, heavy reliance on imports is a major risk for the industry.

Read more: 3 ways to overcome apparel supply chain uncertainty

Few Fashion & Apparel retailers and designers have the capacity to establish in-house production, and creating that capacity in a short period is no mean feat. However, moving away from full package sourcing and outsourcing specific manufacturing processes to US factories is a comparatively easier and more manageable change in production operations that the industry can still explore.

Apparel, footwear, and travel goods represent 6% of US imports, but they contribute to 51% of the tariffs collected by the United States government.

The benefits of a domestic outsourcing production model are obvious: shorter lead times, the flexibility of easier in-season reorders, faster store replenishment, collaborative product design, more direct and on-the-spot quality control, flexibility in production capacity, centralized materials requirement planning (MRP), easier material safety and reorder point management, and, of course, lower tariff costs only paid for material imports.

However, there are many challenges that need to be managed for a successful transition:

Establish strong domestic partnerships with contractors and factories

The single most important aspect is onboarding the right contractors and factories for serving your product lines and categories. Building strong partnerships is essential for securing consistent lead-time commitments from contractors and factories. This requires supply chain visibility by continuously and consistently sharing sales and demand plans of new product lines, reorder and replenishment forecasts, and contractors’ progress reports. It’s essential that you have a domestic production solution that supports such collaboration.

Define production control and material management processes

If your organization relies entirely on full package sourcing, processes for MRP, material purchase, issuance, and consumption are non-existent. Therefore, you don’t have the skillset you need in-house to scale to domestic production. Implementing new processes should focus on recruiting and/or training the right internal resources and setting up IT systems capable of Fashion & Apparel MRP and production management.

Set up warehouse for domestic production

Next, identify the warehouse that will serve the contractors’ and factories’ material requirements. The warehouse has to be located nearby to ensure faster material issuance lead times. Warehouse managers need to allocate floor space and implement efficient material receiving, put-away, picking, and shipping processes. Implementing a digital warehouse management system (WMS) capable of materials management is a must.

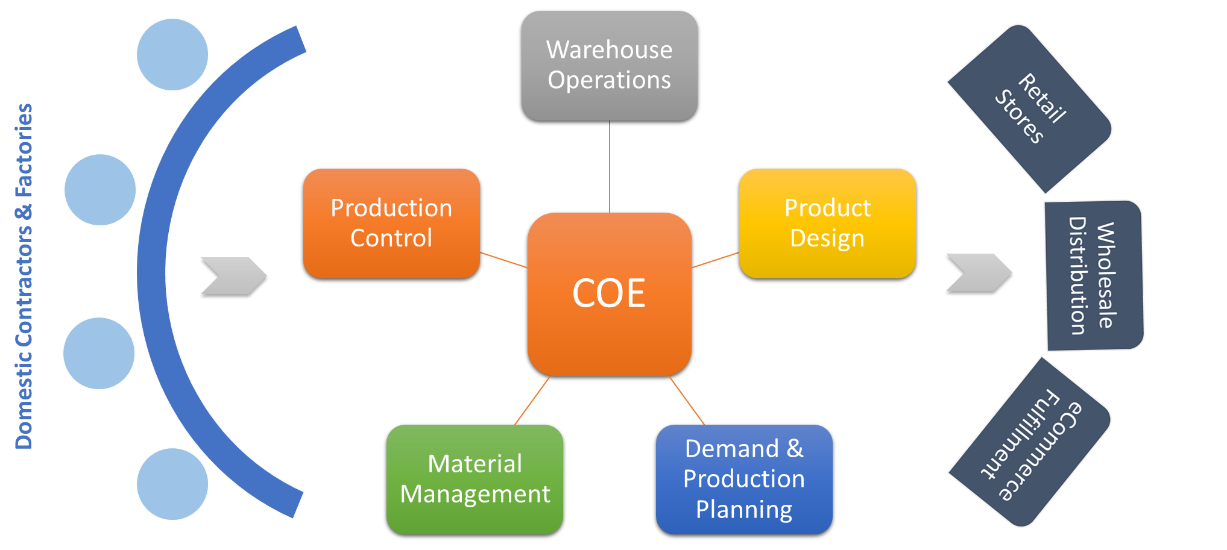

Establish CoE steering committee

Collaborating between different departments to achieve the eventual goal of timely, cost efficient products loved by consumers requires a concerted effort controlled by a steering committee of stakeholders from product design, production control, planning, material management, and logistics & distribution.

![]()

Establishing a Center of Excellence (CoE) steering committee brings your efforts together and keeps your teams focused on their shared objectives. It ensures smooth collaboration with contractors and factories, and allows merchandizers to lead product line success across all sales channels.

Expanding your production operations network isn’t just an onshoring effort to bring production back to domestic markets. It involves taking a fresh look at organizing new process models. Use self-service portals for partners to provide the following capabilities:

- Sharing demand forecast insights

- Visibility to new product lines

- Collaborative sampling processes

- Factory-driven material consumption reporting

- Factory-driven progress reporting

- Sharing estimated capacity requirements for in-season replenishments

To minimize operational costs and maximize ROI, the CoE steering committee should focus on establishing a digital workforce using intelligent/robotic process automation (RPA/IPA). Here are some process areas they could focus on:

- Work order issuance

- Vendor invoicing

- Contractor and vendor onboarding

- Material issuance and allocation

- Material consumption journal entries

- Work order progress reporting

- Material reorders

HauteLogic by Visionet Systems is a comprehensive, ready-to-deploy fashion solution for collaborative domestic Fashion & Apparel sourcing management, with self-service portals for contractors and factories and complete MRP and production control processes that are fully integrated with WMS and retail POS operations. Visionet and HauteLogic provide a full scope of services for establishing a digital workforce by effectively implementing RPA/IPA to enhance Fashion & Apparel operations.

Please contact Visionet Systems today to discover how our complete range of solutions and services are the best choice for your current and future fashion management needs.